Retrofitting Services for CNC Machines – Win Win

🛠 What is CNC Retrofit?

A CNC retrofit is the process of upgrading the CNC controller, axes servo motors and drives, spindle motor and drives, along with portions of the associated wiring and key electromechanical components of a machine tool.

Unlike rebuilding or remanufacturing, CNC retrofitting focuses solely on the control system and drive technology — it does not involve major repairs or replacements of the machine’s mechanical structure.

It is important not to confuse CNC retrofitting with CNC conversion. In a CNC conversion, a manual machine is entirely transformed into a CNC-operated machine. In retrofitting, we upgrade an already existing CNC machine to enhance its performance and extend its working life.

✅ Lowest Cost Solution:

If the machine tool is generally in good mechanical condition, a CNC retrofit is often the most economical method to significantly improve machine performance without investing in a completely new machine.

✅ On-Site Work:

While some sub-assemblies and preparations are handled at our facility, most retrofitting work is completed directly at the customer’s machine site. This eliminates costly machine transportation, rigging expenses, and dramatically reduces downtime.

✅ Difference from Rebuilding:

Rebuilding usually involves repairing or replacing worn mechanical parts such as ball screws, lubrication systems, safety interlocks, guards, belts, hoses, and electrical wiring. It is typically carried out at the rebuilder’s workshop, which may incur extra shipping and handling charges. In contrast, CNC retrofitting focuses mainly on upgrading controls and drive systems.

At Win Win, we specialize in cost-effective CNC retrofitting that brings your machines back to peak operational efficiency — delivering better accuracy, reliability, and longevity without breaking your budget.

🌟 Benefits of CNC Retrofitting

Over the past twenty years, there have been incredible advances in machine tool and CNC technologies.

However, not every machine tool improvement is always necessary for your specific business applications.

Through CNC retrofitting, you can leverage the latest CNC innovations — improved performance, higher reliability, enhanced features — while keeping your existing machine structure intact.

While small commodity machines might be cheaper to replace due to production economies, for mid-to-large machines, CNC retrofitting is a highly cost-effective alternative.

Retrofitting allows you to save significantly on investment costs, engineering charges, and machine downtime.

🚀 Key Advantages of CNC Retrofitting:

✅ Far Superior Repeatability: Maintain precision across production batches without errors.

✅ Reduced Machine Downtime: Minimize production stoppages and keep your operations running smoothly.

✅ Increased Productivity: Faster processing and machining lead to better output and efficiency.

✅ Enhanced Machine Control: Modern CNC systems offer better programmability, flexibility, and ease of use.

✅ Fast Machining Cycles: Achieve rapid machining with optimized CNC controls and drives.

✅ High Accuracy and High Feed-Rates: Improve your cutting speeds without sacrificing precision.

✅ Superior Surface Finishes: Thanks to the latest digital servo drives, achieve greater part finish quality and accuracy.

With a professional CNC retrofit from Win Win, you can breathe new life into your older machines — maximizing performance while minimizing costs.

⚙️ What We Offer at Win Win

At Win Win, we specialize in complete CNC retrofitting solutions with comprehensive electrical, electronic, and mechanical revamping services.

We don’t just upgrade — we redefine the potential of your existing machines by enhancing their precision, performance, and lifespan.

🛠️ Our Approach:

📋 Requirement Analysis:

We begin by carefully studying your machine or project requirements to fully understand your operational needs.🛠️ Conceptualization & Engineering Design:

Our experts conceptualize a technically feasible solution that fits your expectations and application requirements.⚙️ Execution & Implementation:

We execute the retrofit through professional engineering practices — ensuring minimal downtime and maximum efficiency.🎓 Training Your Team:

Post-retrofitting, we train your workforce for effective machine operation and maintenance, empowering you for the future.

🔧 Upgradation Services Include:

✅ Replacement of Leadscrews with Ball Screws

Enhance precision, reduce backlash, and extend machine life.✅ Turcite Replacement and Bed Rebuilding

Upgrade sliding surfaces for better machine accuracy and longer service life.✅ Conversion to Linear Motion Guideways

Achieve smoother, faster, and more accurate machine movements.✅ Tool and Fixture Redesign for HMC/VMC Centers

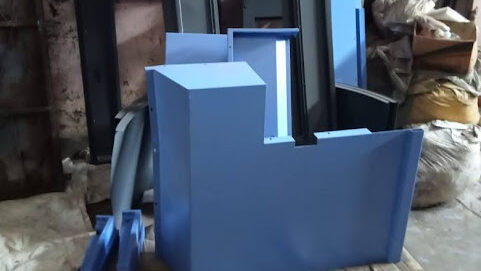

Customized tool and job fixture modification to improve machining performance and flexibility.✅ Electrical Panel Design & Supply

Full panel solutions with all required switchgear and wiring, built for efficiency and reliability.✅ Mechanical Design Modifications

Mechanical enhancements tailored to your unique machine requirements.✅ Complete PLC System Design and Integration

Advanced PLC-based automation to streamline your operations.✅ Full Machine Prove-Out

Thorough machine testing to ensure 100% operational excellence before project handover.

🏆 Why Trust Win Win?

✅ Expertise across CNC Turning Machines, HMCs, VMCs, CNC Grinders, CNC Gantry Milling, CNC Plano Millers, and Universal 5-Axis Machining Centers.

✅ Integration experience with top CNC systems like FANUC, Siemens, and Mitsubishi.

✅ Dedicated customer support and technical excellence.

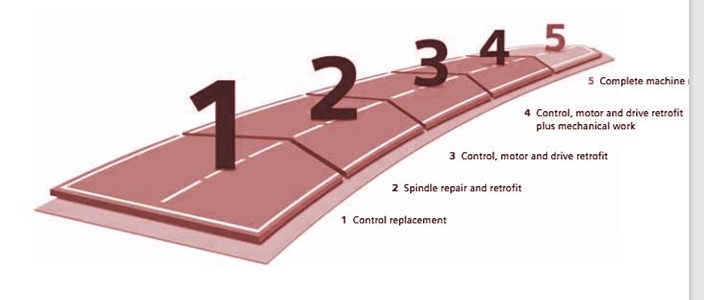

🏭 Our Five Levels of CNC Retrofit

At Win Win, we offer five comprehensive levels of CNC retrofitting, customized to enhance your machine’s performance, precision, and reliability.

Over the years, we have successfully retrofitted a diverse range of machines, from simple to highly complex, delivering exceptional results for industries across India.

🔹 Machines We Have Retrofitted:

CNC Turning Machines with Auto Loader Mechanisms

Horizontal Machining Centers (HMCs)

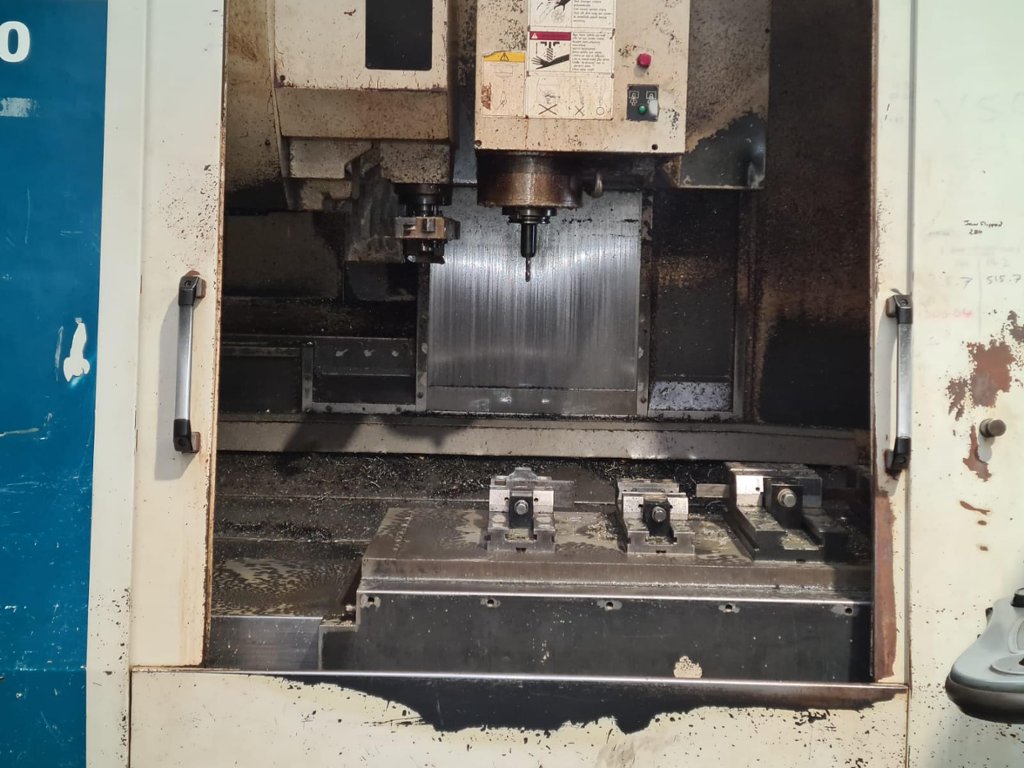

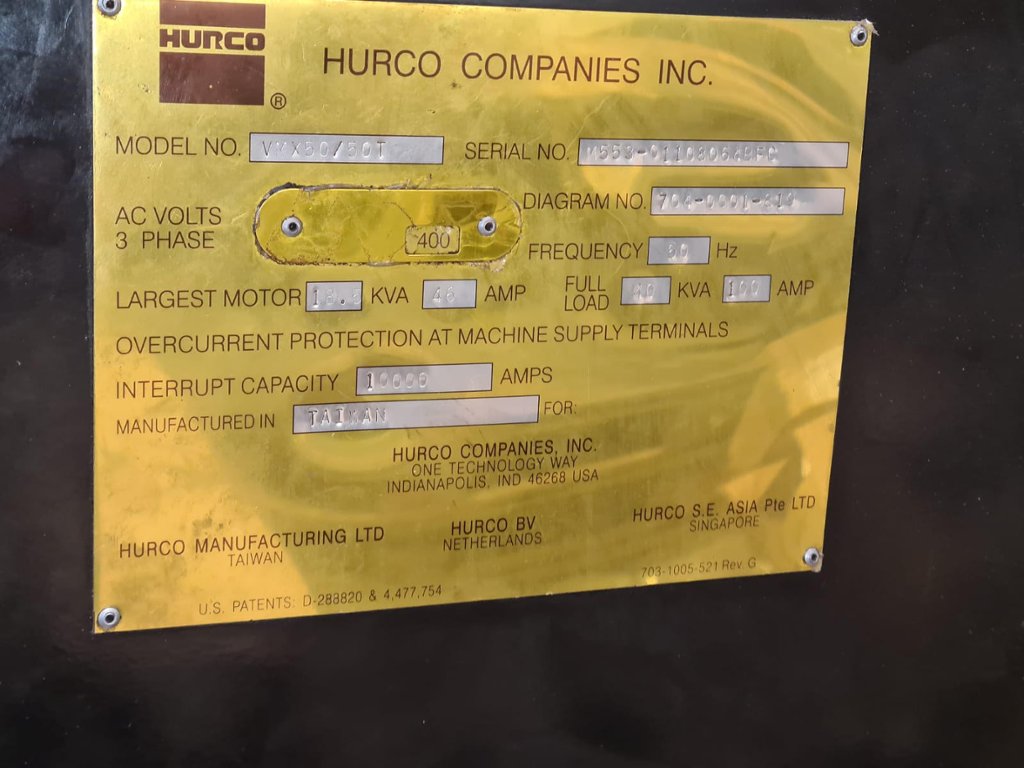

Vertical Machining Centers (VMCs)

CNC Grinders

CNC Gantry Milling Machines

CNC Plano Miller Machines

Universal Machining Centers (5 Axis)

🔹 CNC Systems We Specialize In:

FANUC CNC Controllers

Siemens CNC Systems

Mitsubishi CNC Controllers

We seamlessly integrate the best CNC control systems to ensure smooth operation, superior accuracy, and maximum productivity for your retrofitted machine.